Project Brief

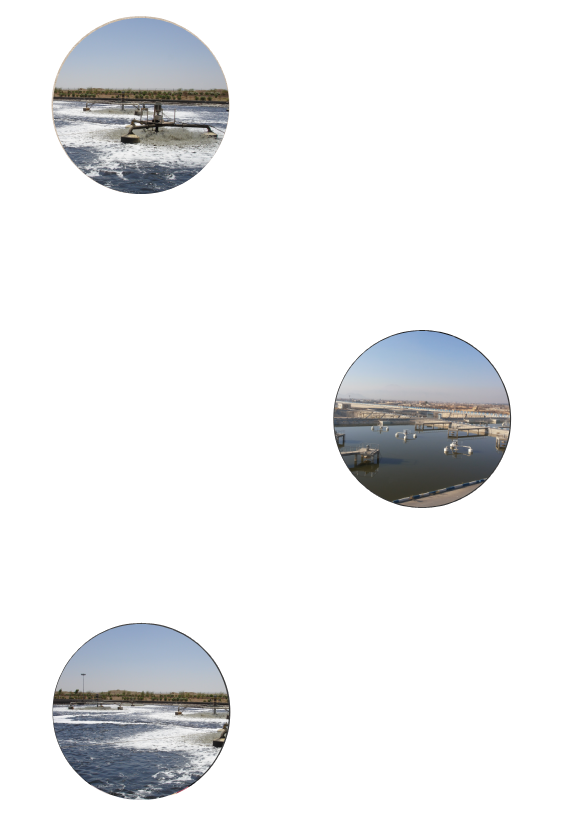

Tertiary treatment is designed based on physical and chemical method, ultrafiltration and reverse osmosis system. Two modules are considered for this plant with average flowrate 10000 m3/d.

Type of agreement for this project is EPC.

Made by

Other project images

Skills Needed

- Environmental engineering,

- Chemical engineering,

- Mechanical engineering,

- Civil engineering,

- Instrumentation and Control engineering.

Initial Concept Planning

Tertiary treatment is designed based on physical and chemical method, ultrafiltration and reverse osmosis system. Two modules are considered for this plant with average flowrate 10000 m3/d. Type of agreement for this project is EPC.

Drafts & Revisions

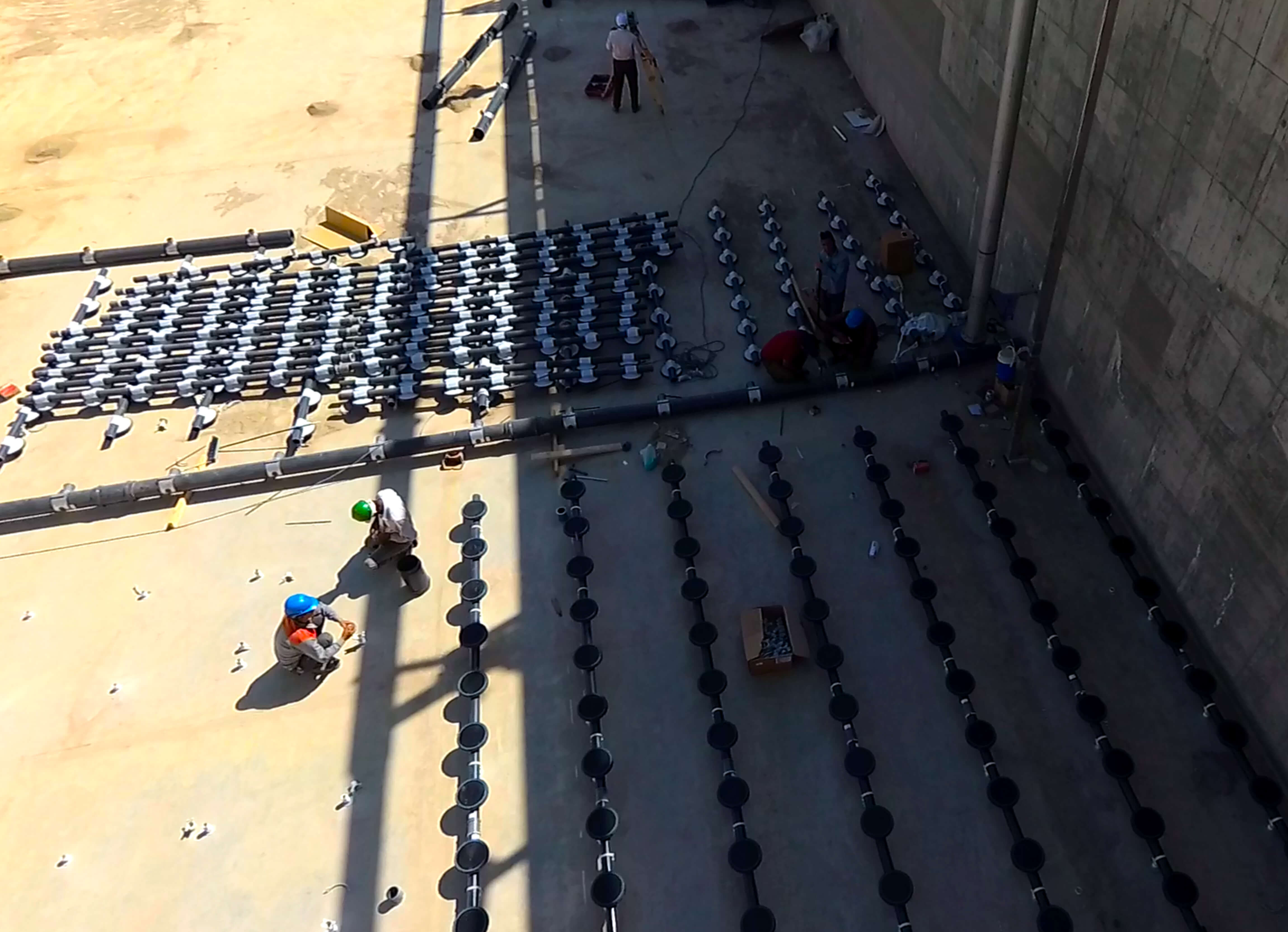

This review has discussed Physical and chemical system including coagulation, flocculation, Dissolved Air Flotation, filtration, ultra filtration and reverse osmosis system and also sludge processing unit in order to reuse of effluent wastewater treatment plant and to reduce the pollution load. This wastewater treatment plant has not been completed and effluent should be met standard of reuse as make up water in power plant.

Other information

Advanced treatment plant is constructed for reusing of treated wastewater. There is a complete process arrangement for treating in order to meet requirement for reuse. Wastewater treatment plant effluent is stored in a storage tank. Disinfection is done by injection of calcium hypochlorite 10% to storage tank.

Full technical specifications

Click here to download the PDF file.

Excellent Results

This project fully met our customer’s expectations.