Target Customers:

- End-Users who want reuse their wastewater

- Consulting Engineers Companies

- Contractors who need design parameters

- Membrane Manufacturers who need to check their modules performance

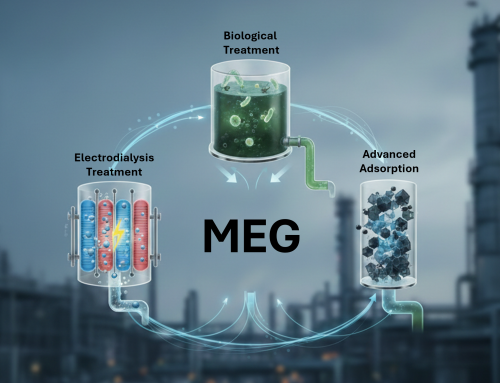

Why Pilot:

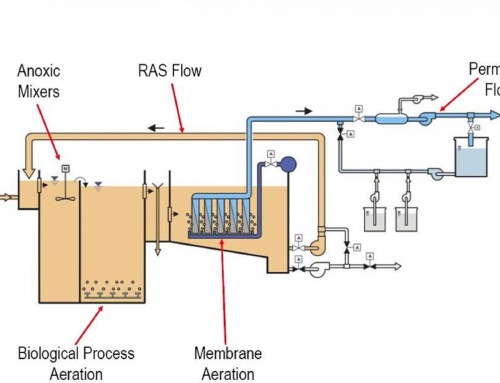

- Finding best flux and then surface area of membranes

- Reality of treated water characteristics then choosing next processes.

- Find out best operation data

- To do performance tests on different MBR modules

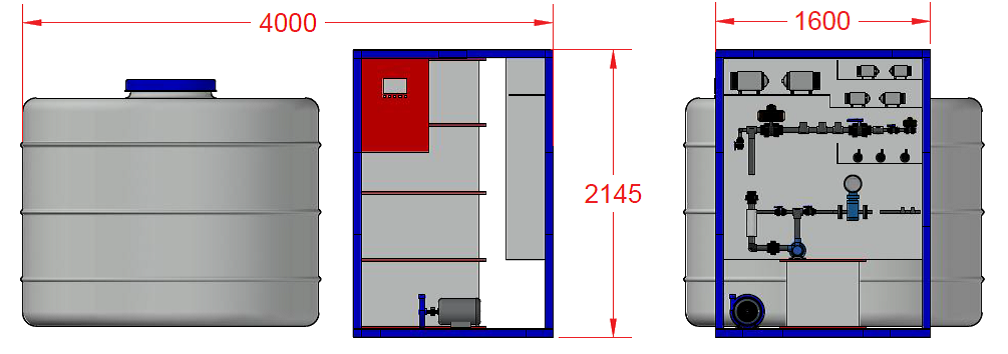

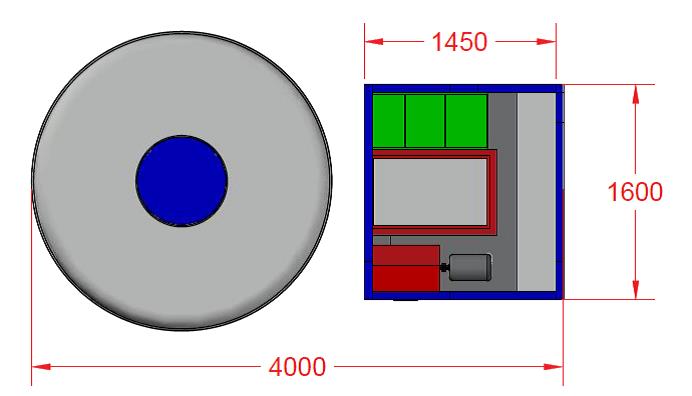

General View:

- Transportable Skid

- Sun light and dust resistance equipment

- UPVC or Stainless-Steel piping

- Chemical cleaning by automatic system-flux enhancing

- Continues or batch operation

- Protection to prevent membrane damage

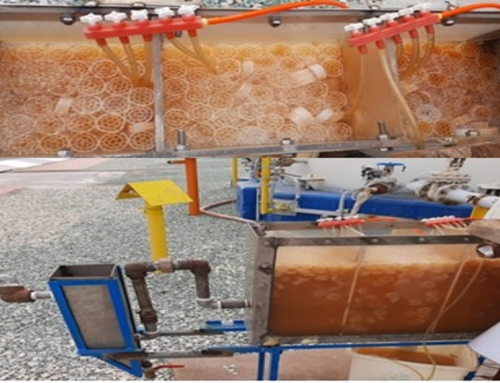

Hollow Fiber

Technical Data:

Operation capacity: 300-600 lit/h

- Including Separate Biological and MBR tanks

- Max Membrane area: 30m2

- 5000 lit Biological Tank

- 1000 Lit MBR tank with HDPE materialPermeate pump with controlling rate

- RAS pump with 5Q capacity

- Chemical dosing for Maintenance Cleaning (MC)

- Separate aeration blowers for Biological and Membrane scouring

- Air compressor and pneumatic valves

- Instruments:

- Online Magnetic flow meters

- Level sensors

- Pressure sensors

- Control:

-

- PLC and finger touch HMI

- Full automatic operation and cleaning

- VFDs for air and water flows

-