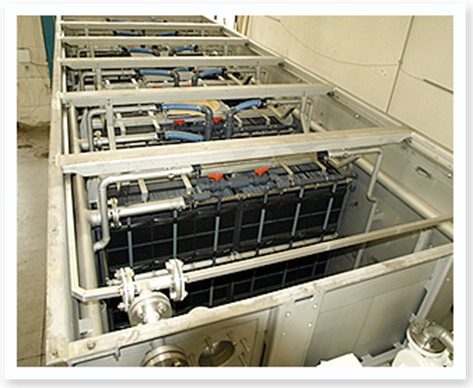

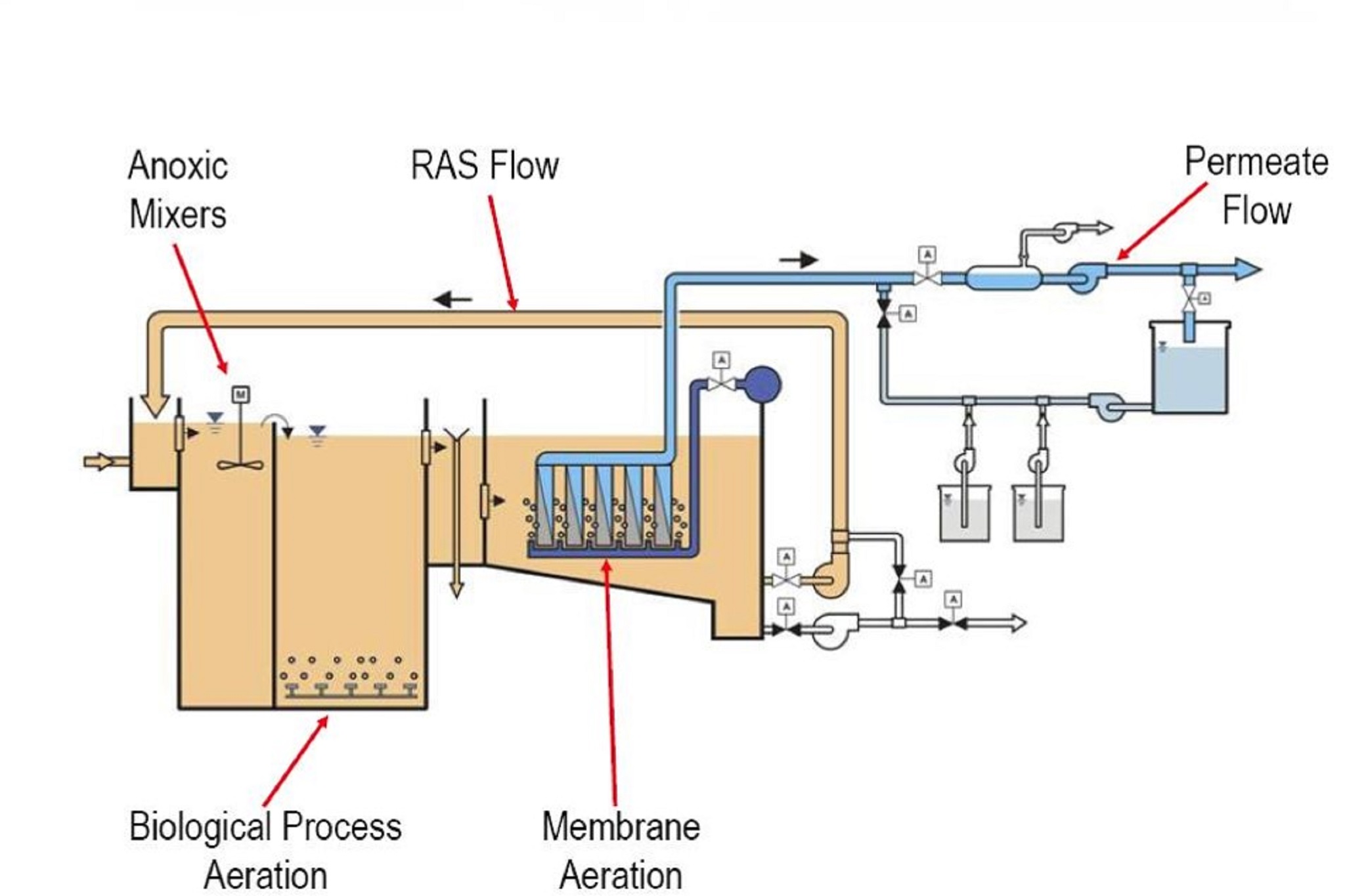

it is one of the newest rapidly growing sewage treatment technologies in this industry. MBR membranes replace sedimentation, sand filtration and disinfection methods that were used in traditional methods of activated sludge . MBR submerged modules locate in a biological tank (active sludge) or in a lateral tank, under vacuum operation, while the biomass remains behind the membrane, .Water passes through and out of the membrane and the module. MBR systems, in addition to their high output quality, occupy less space than traditional systems, and are more resistant to input shocks.

MBR technology makes a biological process with a long life of sludge (usually between 20 and 100 days) and an increase in MLSS concentration in the range of 8000-15000 mg / l. High concentrations of MLSS and high SRTs will result many benefits, including stabilizing activated sludge, full nitrification, and reducing excess sludge production. High concentration of MLSS also reduces the amount of aeration required by 30 to 50 percent compared to the traditional method.

EET WATER MBR Services

-Design and Supply MBR plants

-MBR modules selection

-MBR replacement Services

-Upgrading existing conventional plants to MBR

-Supervision for Installation and start up

-MBR plants trouble shooting