1. Microplastics in Wastewater as Emerging Contaminants

1.1 Presence and Environmental Relevance

Microplastics are increasingly recognized as emerging contaminants in wastewater treatment systems due to their persistence, small size, and resistance to degradation. Conventional wastewater treatment plants were not originally designed to target microplastic particles, resulting in incomplete removal and the potential release of residual microplastics into receiving water bodies. Recent studies highlight the need for advanced and integrated treatment configurations to improve removal efficiency, particularly in industrial and high sensitivity wastewater applications.

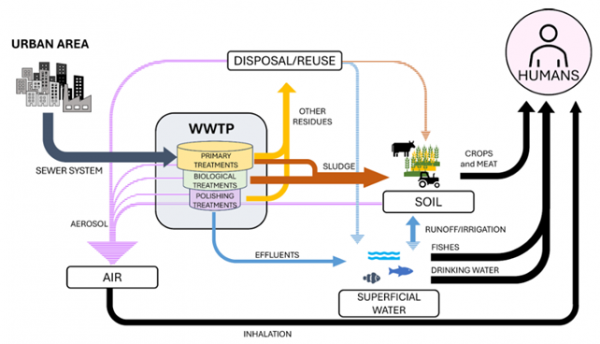

1.2 Sources and Entry Pathways

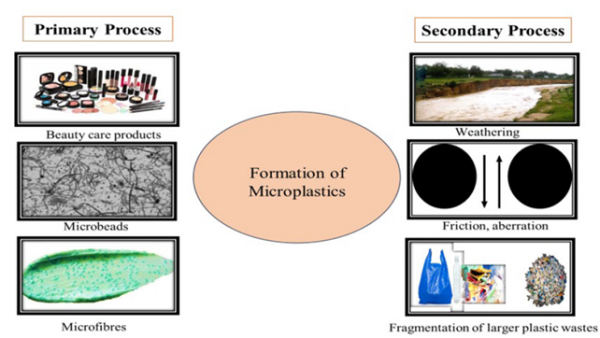

Microplastics enter wastewater streams from a wide range of sources, including domestic activities, industrial discharges, synthetic textiles, personal care products, and the fragmentation of larger plastic materials. Once transported to wastewater treatment plants, these particles exhibit diverse physical and chemical characteristics that strongly influence their fate during treatment.

Scientific evidence shows that microplastics are consistently detected in both influent and effluent streams of wastewater treatment plants. Their persistence in treated effluents underscores the limitations of conventional treatment processes and supports their classification as emerging contaminants requiring targeted removal strategies.

2. Occurrence and Physical Characteristics of Microplastics

Microplastic particles in wastewater vary significantly in:

- Size, from visible fragments to micrometric and sub-micrometric particles

- Shape, including fibers, fragments, films, and pellets

- Polymer composition, such as polyethylene (PE), polypropylene (PP), and polystyrene (PS)

Among these categories, fibrous microplastics are frequently reported as the dominant form. Their elongated geometry and flexibility contribute to their persistence during treatment and increase the likelihood of passage through conventional separation processes, as reported by recent research on microplastic behavior in wastewater.

3. Performance of Conventional Wastewater Treatment Processes

3.1 Primary Treatment

Primary treatment processes, such as screening and sedimentation, can remove a fraction of larger and denser microplastic particles. Removal efficiency at this stage is highly variable and strongly dependent on particle size, density, and morphology. Smaller, buoyant, or irregularly shaped particles are poorly captured during primary treatment, according to recent studies on wastewater treatment performance.

3.2 Secondary Treatment

Secondary treatment processes, primarily designed for organic matter degradation, contribute to microplastic removal through physical entrapment within activated sludge flocs. While secondary treatment represents a major removal step for many particles, measurable concentrations of microplastics often remain in secondary effluents, particularly fibers and fine particles.

These findings indicate that biological treatment alone is insufficient to ensure complete microplastic removal, as highlighted by scientific reviews on emerging contaminants.

4. Role of Advanced and Tertiary Treatment Stages

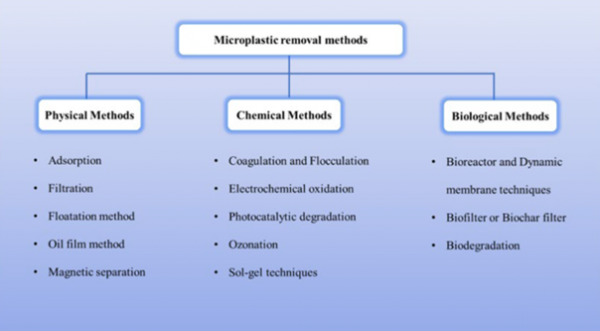

Advanced treatment stages play a critical role in enhancing microplastic removal performance. Filtration and advanced separation technologies significantly reduce microplastic concentrations, especially for particles not effectively removed during earlier stages.

Even advanced systems do not consistently achieve full elimination. This reflects the fact that conventional treatment plants are optimized for organic matter, nutrients, and suspended solids, rather than emerging contaminants such as microplastics.

5. Electrocoagulation and Membrane-Based Removal Processes

5.1 Electrocoagulation for Particle Aggregation

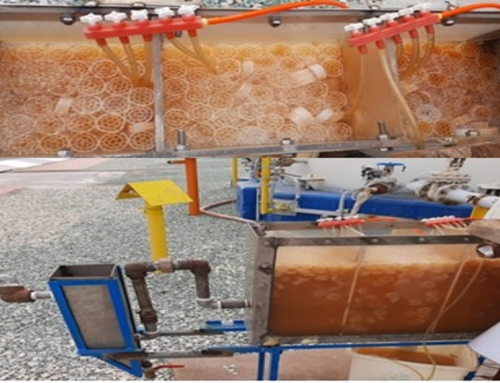

Electrocoagulation has emerged as a promising technique for microplastic removal due to its ability to destabilize and aggregate suspended particles through the in situ generation of coagulant species. Recent experimental studies demonstrate that electrocoagulation significantly enhances particle aggregation, increasing effective particle size and improving subsequent separation efficiency.

This process is particularly effective when integrated into a multi-stage treatment system rather than applied alone. Electrocoagulation is especially relevant for industrial wastewater applications, where flexibility, process control, and reduced reliance on external chemical dosing are advantageous.

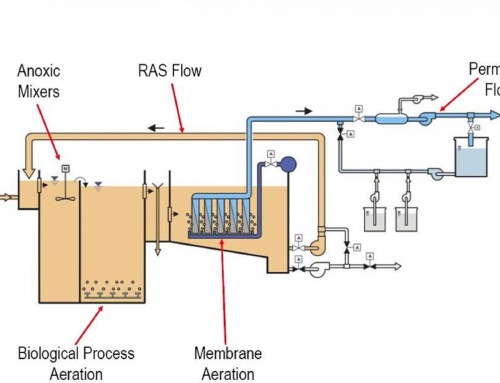

5.2 Membrane Filtration as a Physical Separation Barrier

Membrane filtration provides a physical barrier capable of retaining aggregated microplastic particles. When applied downstream of electrocoagulation, membrane filtration substantially increases overall removal efficiency and enhances process stability.

Operational challenges such as fouling and scaling, particularly in complex wastewater streams, highlight the importance of proper pre-treatment and process integration.

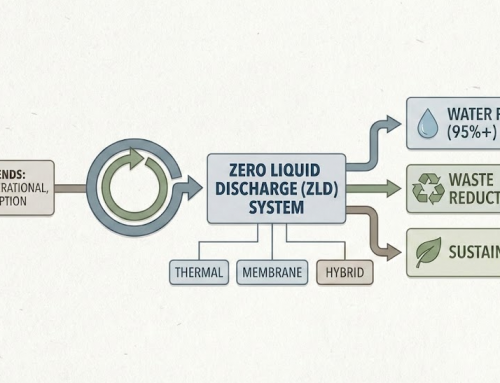

6. Hybrid and Integrated Treatment Systems

6.1 Process Integration Strategies

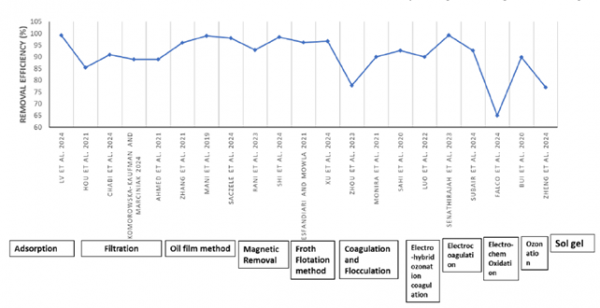

Hybrid treatment systems consistently outperform single-process approaches. Scientific reviews emphasize that effective microplastic removal requires a combination of physical, chemical, and integrated strategies to address the wide diversity of particle sizes, shapes, and surface properties.

Integrated configurations may combine physical separation processes, including filtration, sedimentation, flotation, and membrane systems, with coagulation and flocculation to promote particle aggregation and improve capture efficiency. Electrocoagulation generates coagulants in situ to enhance aggregation without external chemical dosing, while adsorption-based approaches using activated carbon or bio-based materials support the removal of fine particles.

6.2 Performance Advantages of Hybrid Systems

These hybrid systems provide higher removal efficiency, greater operational reliability, and adaptability to complex industrial or pharmaceutical effluents. Physical separation methods are particularly effective as tertiary or polishing steps, while coagulation and electrocoagulation improve capture of smaller, flexible fibers. Adsorption complements these processes by targeting particles that are otherwise difficult to remove.

7. Practical Implications and System Limitations

7.1 Factors Influencing Removal Efficiency

Microplastic removal performance is influenced by particle size, particle shape-particularly the persistence of fibers-polymer density and surface properties, and treatment configuration and process integration. These factors explain the wide variability in reported removal efficiencies across treatment plants.

7.2 Limitations of Existing Infrastructure

Current wastewater treatment systems were not designed with microplastic removal as a primary objective. As a result, complete removal cannot be consistently achieved, fine particles may pass through multiple treatment stages, and removal performance varies significantly between facilities. These limitations underline the need for continued research, monitoring, and optimization.

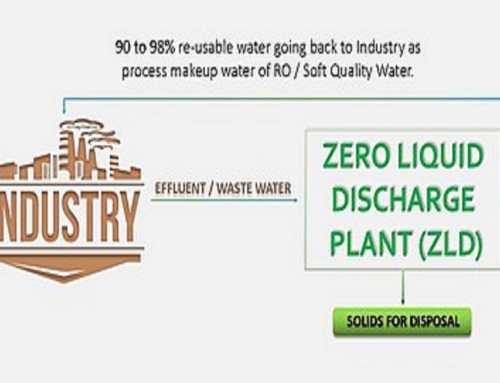

8. Relevance for Industrial and Pharmaceutical Wastewater Treatment

Microplastic contamination is especially critical in industrial, pharmaceutical, and high-sensitivity applications, where effluent complexity and strict environmental standards prevail. Advanced and integrated treatment configurations are essential to manage emerging contaminants alongside conventional wastewater parameters.

Understanding microplastic behavior and removal mechanisms supports tailored treatment strategies suitable for industrial-scale implementation.

9. Key Technical Insights and Research Direction

Current evidence indicates that microplastic particles can bypass conventional wastewater treatment, particle aggregation is critical for effective removal, standalone treatment steps show limited effectiveness, and hybrid and integrated systems offer the most reliable performance.

These findings align with trends toward next-generation wastewater treatment solutions capable of addressing emerging contaminants while maintaining operational efficiency and regulatory compliance.

Stay tuned! We will publish a second part to go into more detail.

The sources of the images and articles used to write this text are available in this downloadable file: Click here!