Monoethylene glycol (MEG) is widely used in the oil and gas industry as a gas hydrate inhibitor during gas production, processing, and transportation. As a result of gas processing and MEG regeneration operations, large volumes of industrial wastewater containing significant concentrations of MEG are generated. These effluents are often characterized by high chemical oxygen demand (COD), elevated salinity, and complex chemical composition, posing environmental and regulatory challenges if discharged without appropriate treatment.

Due to the diversity of wastewater characteristics, multiple treatment technologies have been investigated to address both MEG removal and desalination requirements. Among these, biological treatment, electrodialysis, advanced adsorption processes represent the most relevant and complementary approaches.

1. Biological Treatment Using Sequencing Batch Reactor (SBR)

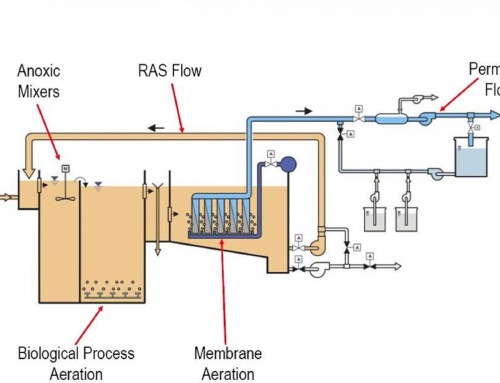

Biological treatment using aerobic Sequencing Batch Reactor (SBR) has been evaluated as a cost-effective approach for MEG removal from industrial wastewater with high organic load and moderate salinity.

1.1 Feasibility of Biological MEG Removal

Aerobic biological treatment successfully removed MEG from industrial wastewater. Microorganisms sourced from a sanitary wastewater treatment plant adapted to MEG and biodegraded it under controlled operating conditions, demonstrating the feasibility of biological MEG removal.

1.2 Multi-Stage Treatment Performance

Reactor performance was evaluated under three MEG loading conditions:

- Stage 1 (Low MEG concentration): MEG removal efficiency exceeded 80% within four days, reaching nearly complete removal after stabilization of microbial activity

- Stage 2 (Moderate MEG concentration): Removal efficiency decreased to around 20%, indicating that hydraulic residence time and reactor capacity were insufficient for higher organic loading.

- Stage 3 (High MEG concentration – real industrial wastewater): With increased residence time, MEG removal efficiency exceeded 70% after seven days, demonstrating that even high-strength MEG wastewater can be biologically treated if adequate contact time is provided.

1.3 Hydraulic Residence Time Influence

Hydraulic residence time (HRT) was identified as a critical parameter controlling MEG biodegradation efficiency. Increased residence time allows to improve microbial adaptation and enhanced MEG metabolism, significantly improving treatment performance at high influent concentrations.

1.4 Operational Stability (pH and Dissolved Oxygen)

Dissolved oxygen (DO) was maintained in the range of 1.5–4.5 mg/L, supporting aerobic biodegradation. pH gradually decreased due to acidic by-products, emphasizing the need for pH control in long-term operation. Stable operating conditions are critical for sustained MEG removal performance.

1.5 Industrial Relevance and Applications

From an industrial perspective, this study demonstrates that SBR technology:

- Can treat MEG-containing industrial wastewater

- Is suitable for oil and gas facilities and MEG regeneration units

- Can handle high MEG concentrations with sufficient residence time

- Offers a flexible and scalable biological treatment solution

This approach is particularly relevant for:

- Refineries and gas processing plants

- MEG regeneration and loss streams

- Facilities seeking cost-effective and environmentally friendly treatment options

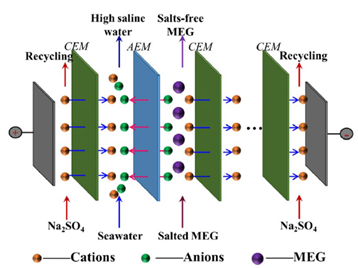

2. Electrodialysis Treatment of MEG-Containing Hypersaline Wastewater

Electrodialysis (ED) is an electrically driven membrane process that selectively transports ionic species through ion-exchange membranes while largely retaining non-ionic compounds such as MEG. This characteristic makes ED particularly suitable for the treatment of hypersaline industrial wastewater where desalination must be achieved without excessive MEG loss.

2.1 Applicability of Electrodialysis for MEG Wastewater

The studies confirm that electrodialysis is technically feasible for the treatment of hypersaline MEG-containing wastewater. The process achieves effective salt removal while maintaining minimal MEG losses, making it suitable for industrial contexts where desalination and glycol preservation are both required.

2.2 Salt Removal Performance

Electrodialysis achieved salt removal efficiencies ranging from 56% to 89%, depending on operating conditions. Both monovalent and divalent ions (sodium, potassium, calcium, magnesium, chloride, and sulfate) were successfully transported across ion-exchange membranes. Ion migration followed predictable trends governed by ionic charge, mobility, and membrane selectivity, supporting stable and controllable desalination performance.

2.3 MEG Transport and Retention

MEG is a non-ionic compound and is therefore not directly driven by the applied electric field during electrodialysis. MEG transfer across membranes occurred only indirectly due to cotransport phenomena associated with salt migration. Measured MEG losses remained very low:

- 29–1.60% MEG loss, even at high salt removal levels

This behaviour supports the use of electrodialysis for desalination while enabling MEG recovery or reuse.

2.4 Influence of Operating Conditions

Both batch and continuous electrodialysis configurations were evaluated. The results indicate that:

- Higher voltage and flow velocity increased salt removal but also slightly increased MEG transport

- Optimal operating conditions achieved a balance between high desalination efficiency and minimal MEG leakage.

- Continuous multistage ED systems were identified as particularly suitable for industrial and offshore applications due to compact design and operational stability.

2.5 Technology Advantages for Industrial Applications

Based on the findings of this study, electrodialysis offers several advantages for treating MEG-containing wastewater:

- Effective removal of high salt concentrations

- Very low MEG loss during treatment

- Suitability for continuous operation

- Compact system design

- Reduced environmental footprint compared to thermal processes

3. MEG Removal by Advanced Adsorption Technology

Adsorption-based treatment has been investigated as an effective technology for direct MEG removal from industrial wastewater, particularly where discharge limits or COD reduction requirements cannot be met by desalination or biological treatment alone.

3.1 Adsorption as an Effective MEG Removal Strategy

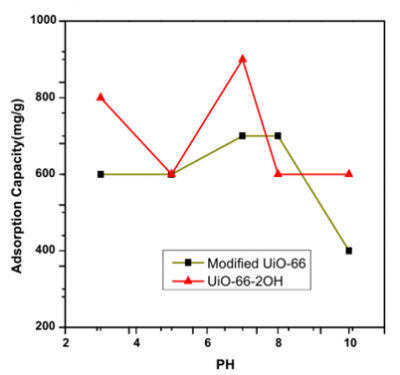

The studies demonstrate that adsorption is a practical and efficient approach for MEG removal, especially in cases where biological or membrane-based processes face operational limitations. Advanced zirconium-based metal–organic frameworks (MOFs) exhibited exceptionally high affinity for MEG under realistic wastewater conditions.

3.2 Adsorbent Performance and MEG Removal Capacity

Two MOF adsorbents were evaluated:

- Modified UiO-66

- UiO-66-2OH (hydroxyl-functionalized)

Key performance results include:

- Maximum adsorption capacity of 800 mg of MEG per gram for modified UiO-66

- Maximum adsorption capacity of 1000 mg of MEG per gram for UiO-66-2OH

- Removal efficiencies exceeding 90% at lower MEG concentrations under neutral Ph

These results indicate that MOF-based adsorption can outperform conventional adsorbents used in industrial wastewater treatment.

3.3 Influence of pH and Operating Conditions

Adsorption efficiency was highest at neutral pH (around pH 7), typical of many industrial effluents. UiO-66-2OH consistently showed superior performance due to hydroxyl functional groups that enhance hydrogen-bond interactions with MEG molecules. Only limited performance loss was observed under acidic or strongly basic conditions.

3.4 Adsorption Kinetics and Stability

The adsorption process followed a pseudo-first-order kinetic model, indicating fast uptake of MEG. Most MEG removal occurred during the early stages of contact time, supporting efficient treatment within practical operating periods. Mass transfer was governed by diffusion into the porous structure of the adsorbent, followed by equilibrium adsorption inside the pores. These characteristics are favourable for both batch and continuous treatment systems.

MEG adsorption occurred mainly through physical adsorption and hydrogen bonding, rather than irreversible chemical reactions. The porous structure and high surface area of the MOFs provided abundant adsorption sites. Regeneration tests showed that the adsorbents retained a significant portion of their removal efficiency over multiple cycles, indicating good operational stability. This makes the technology suitable for repeated use and long-term operation in industrial wastewater treatment systems.

3.5 Industrial Applicability

From a wastewater treatment perspective, this study demonstrates that MOF-based adsorption:

- Is highly effective for treating MEG-containing industrial effluents

- Can significantly reduce MEG concentration and COD

- Operates efficiently under neutral pH conditions

- Offers high adsorption capacity with relatively small amounts of adsorbent

- Is suitable for polishing steps, emergency treatment, or treatment of high-strength MEG wastewater

This technology is particularly relevant for:

- Oil and gas processing facilities

- MEG recovery units

- Industrial wastewater streams with high organic load

4. Overall Conclusions and Integrated Treatment Strategy

Due to the diverse composition of MEG-containing industrial wastewater, no single treatment technology is universally sufficient. Electrodialysis provides an effective solution for the desalination of hypersaline wastewater while maintaining very low MEG losses, enabling environmental compliance and resource preservation. Advanced adsorption technologies offer high-efficiency MEG removal under mild operating conditions, with fast kinetics and good reusability, making them suitable as polishing steps or targeted treatment for high-strength MEG effluents. Biological treatment using aerobic sequencing batch reactors represents a cost-effective and environmentally friendly approach for MEG degradation, particularly when appropriate hydraulic residence time and operational control are applied.

An integrated treatment approach combining electrodialysis, adsorption, and biological processes allows flexible system design based on wastewater characteristics, discharge limits, and reuse objectives. Such integrated solutions ensure reliable MEG removal, operational stability, and long-term environmental compliance while optimizing energy consumption, chemical usage, and overall treatment performance.

The sources of the images and articles used to write this text are available in this downloadable file: Click here!