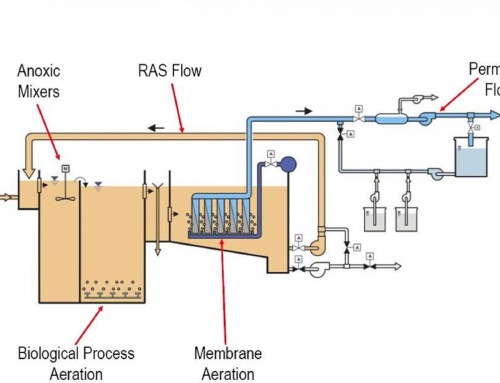

In the attached growth process, microorganisms grow on media such as plastic, stone, etc. The media in the aeration tank can be either a flotation bed or a fixed bed.

The microorganisms attached to the solid surfaces are primarily from the heterotroph group of activated sludge, which use organic carbon as a food source for biomass production.

For the formation of the biofilm on the media, the components on the media are: bed (support), biofilm, film liquid, and bulk liquid, respectively. On the biofilm surface, a resident layer separates the biofilm from the mixed liquid.

Nutrients and oxygen penetrate through this resident layer into the biofilm. On the other hand, the products of biological degradation diffuse from the biofilm layer to the bulk liquid. These processes are performed continuously.

Attached microorganisms cause the growth of dense, viscous, or gel-like layers. As the microorganisms grow, the biomass on the media increases and thickens. The thickening of this layer affects the access of oxygen and nutrients for the microorganisms.

The treatment of wastewater by the Moving Bed Biofilm Reactor (MBBR) method is actually the same as the activated sludge method, with the difference that media are added to the aeration tank to increase the contact area and, consequently, increase the Chemical Oxygen Demand (COD) removal efficiency. Additionally, the volume of the aeration tank is reduced due to the growth of the biofilm on the media. The required air for moving the media and supplying oxygen to the microorganisms is provided by an air blower. After the air contacts the wastewater, some of the oxygen in the air dissolves into the wastewater, thus supplying the oxygen needed by the microorganisms.

The results of this study showed that:

-

The treatment of wastewater from petrochemical industries is possible using a biological method, with the reduction of COD to below approximately 60 mg/L.

-

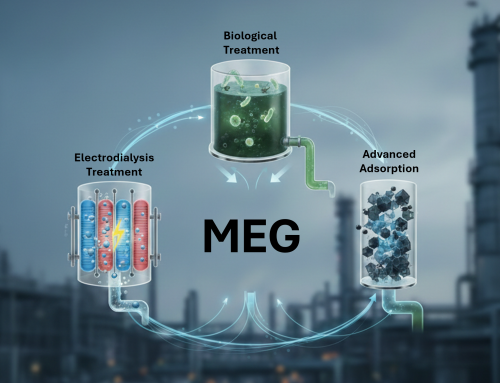

The COD removal rate from the MEG unit wastewater using the MBBR process was over 82%.