Zero Liquid Discharge (ZLD) is a water-treatment strategy that aims to eliminate liquid discharge by maximizing water reuse and converting dissolved salts into recoverable solids. ZLD technologies include thermal processes, membrane processes, and hybrid systems.

1. Thermal Technologies in Zero Liquid Discharge

1.1 Evaporation

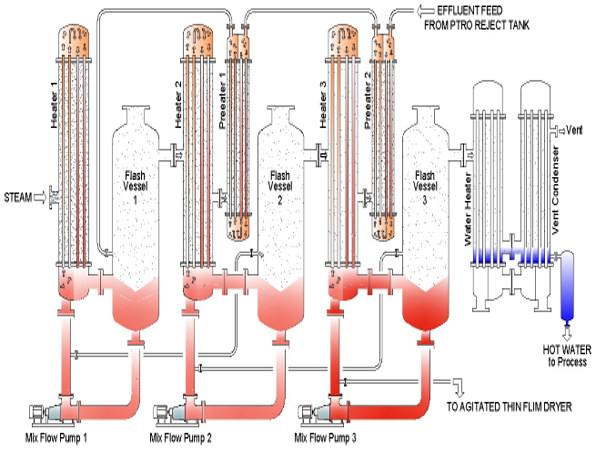

Thermal processes play a central role in many ZLD schemes. Evaporation involves heating wastewater to separate water vapor from dissolved and suspended solids; the vapor is then condensed into high-purity distillate.

As salinity increases, evaporation becomes more energy-intensive because highly concentrated brines require greater heat input.

1.2 Crystallization

Crystallization, typically following evaporation, drives the brine to supersaturation so that salts precipitate as solid crystals. This stabilizes the waste stream and produces solids that can potentially be reused or safely disposed of, but crystallization is also one of the most energy-demanding components of ZLD.

1.3 Evaporation and Crystallizer Units

Evaporation units—such as mechanical vapor recompression (MVR) systems, multiple-effect evaporators (MEE), and conventional evaporators—provide robust separation and consistently produce high-quality water.

Crystallizers (forced-circulation, suspension, or evaporative) introduce additional complexity because they must precisely control nucleation and crystal growth.

1.4 Advantage and Disadvantage of Thermal Processes

Advantages include the ability to treat high-salinity or complex waste streams, deliver almost- complete water recovery, and tolerate contaminants such as organics and heavy metals.

Disadvantages include high thermal energy consumption, substantial CAPEX, scaling and fouling risks in heat exchangers, and the need for careful management of the resulting solid salts.

1.5 Cost Considerations for Thermal ZLD

Thermal processes are typically the largest contributors to both CAPEX and OPEX.

OPEX is dominated by thermal energy demand, while CAPEX increases with corrosion-resistant materials and plant size. Waste-heat integration or MVR can reduce costs, but thermal ZLD remains significantly more expensive than membrane-only approaches.

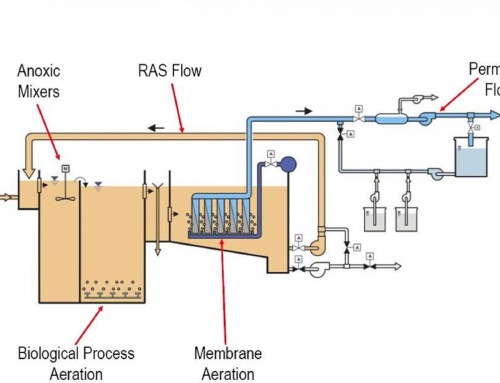

2. Membrane Technologies in Zero Liquid Discharge

2.1 Reverse Osmosis (RO)

Reverse osmosis (RO) uses a semi-permeable membrane and applied pressure to separate water from salts, achieving high recovery while reducing the volume that must be treated thermally.

However, RO performance decreases sharply at high salinity, limiting its ability to treat hypersaline brines.

2.2 Electrodialysis (ED) and Bipolar ED

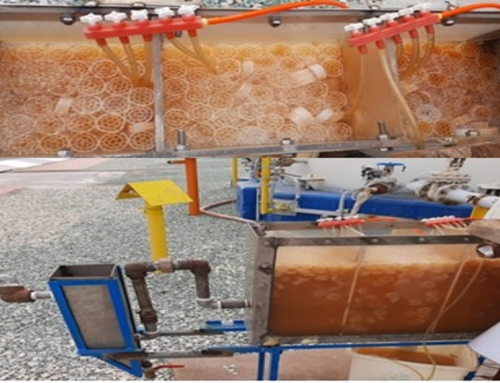

Electrodialysis (ED) uses an electric potential to drive ions across selective membranes, providing efficient salt separation at low to moderate salinities.

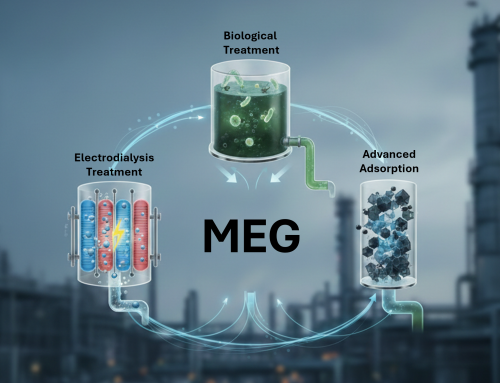

Bipolar electrodialysis (B-ED) can generate acid/base streams and concentrate brines beyond RO limits, reducing the workload of downstream thermal units.

2.3 Advantage and Disadvantage of Membrane Processes

Advantages include lower energy demand, modular design, smaller footprint, faster deployment, and high-quality permeate suitable for reuse.

Disadvantages include fouling and scaling, limited ability to treat very high salinities without hybrid configurations, chemical consumption, and energy use that scales with pressure (RO) or electric current (ED).

2.4 Cost Considerations for Membranes

RO systems typically incur moderate CAPEX and moderate OPEX. ED and B-ED may achieve lower OPEX under favourable ionic loads, although electricity use and membrane replacement remain major cost drivers.

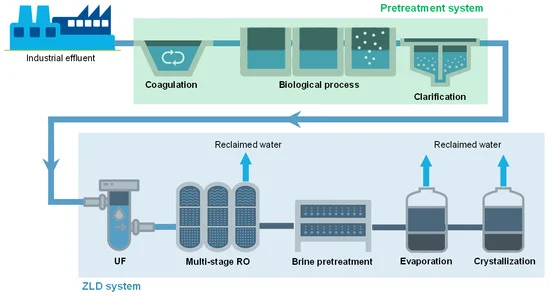

3. Hybrid ZLD Systems

3.1 Combining Membrane and Thermal Processes

Modern facilities increasingly adopt hybrid ZLD systems that strategically combine membranes and thermal technologies.

A typical sequence is:

- Pre-treatment

- RO (or RO + ED) for bulk water recovery

- Further concentration via ED/B-ED

- Final evaporation and crystallization

This staged approach optimizes energy use, minimizes thermal equipment size, and increases overall robustness.

3.2 Advantage and Disadvantage of Hybrid Systems

Advantages include optimized energy balance, reduced thermal duty, improved equipment lifetime, and opportunities to recover salts and chemicals.

Disadvantages include increased process complexity, higher engineering and integration requirements, and the management of multiple waste streams.

3.3 Cost Dynamics

Hybrids typically have higher CAPEX than membrane-only systems but lower lifecycle OPEX than thermal-only ZLD due to the dramatic reduction in energy-intensive thermal steps.

4. Emerging Technologies and Efficiency Improvements

A key area of development involves advanced membranes, such as bipolar electrodialysis, which can concentrate highly saline solutions and reduce thermal evaporator loads.

Despite benefits—water savings, energy reduction, and resource recovery—challenges remain, including high investment costs, energy demand, residual solids management, and environmental impacts.

5. Practical Considerations in ZLD Design and Operation

Key factors influencing ZLD performance and cost include:

- Energy consumption (dominant OPEX component)

- Chemicals and consumables (anti-scalants, cleaning agents, membranes, electrodes)

- Maintenance and labor, especially for membrane cleaning and crystallizer operation

- Solid disposal or valorization

- CAPEX drivers such as corrosion-resistant materials, evaporator size, and control systems

ZLD plants often require robust construction and advanced instrumentation compared with conventional wastewater facilities.

6. Environmental and Sustainability Implications

Life-cycle assessments (LCA) are increasingly used to evaluate the environmental impacts of different ZLD configurations.

They help clarify trade-offs between water recovery benefits and broader environmental burdens such as energy use, emissions, and chemical consumption.

Policymakers and plant owners must consider:

- Local electricity carbon intensity

- Opportunities for waste-heat recovery

- Regulatory drivers

- Environmental impacts of chemical use and solid-waste handling

7. Global Trends in ZLD Adoption

The global trend shows growing interest in Zero Liquid Discharge, driven by:

- Stricter environmental regulations

- Increasing water scarcity

- Circular-economy principles

The long-term goal is to make water treatment more resource-efficient, cost-effective, and environmentally sustainable, achieving high recovery while minimizing operational and environmental burdens.

We will discuss this in more detail in upcoming articles.

The sources of the images and articles used to write this text are available in this downloadable file: Click here!